Back to Technical Work Overview

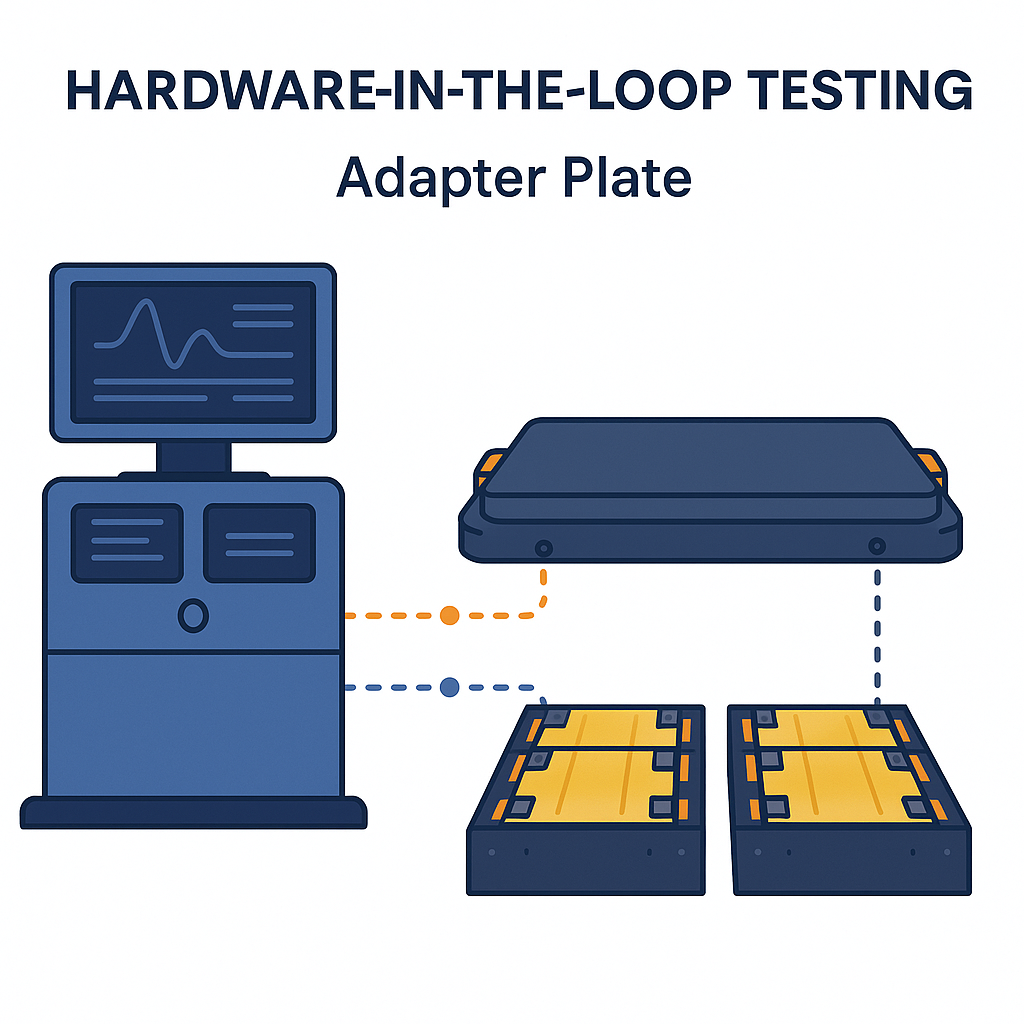

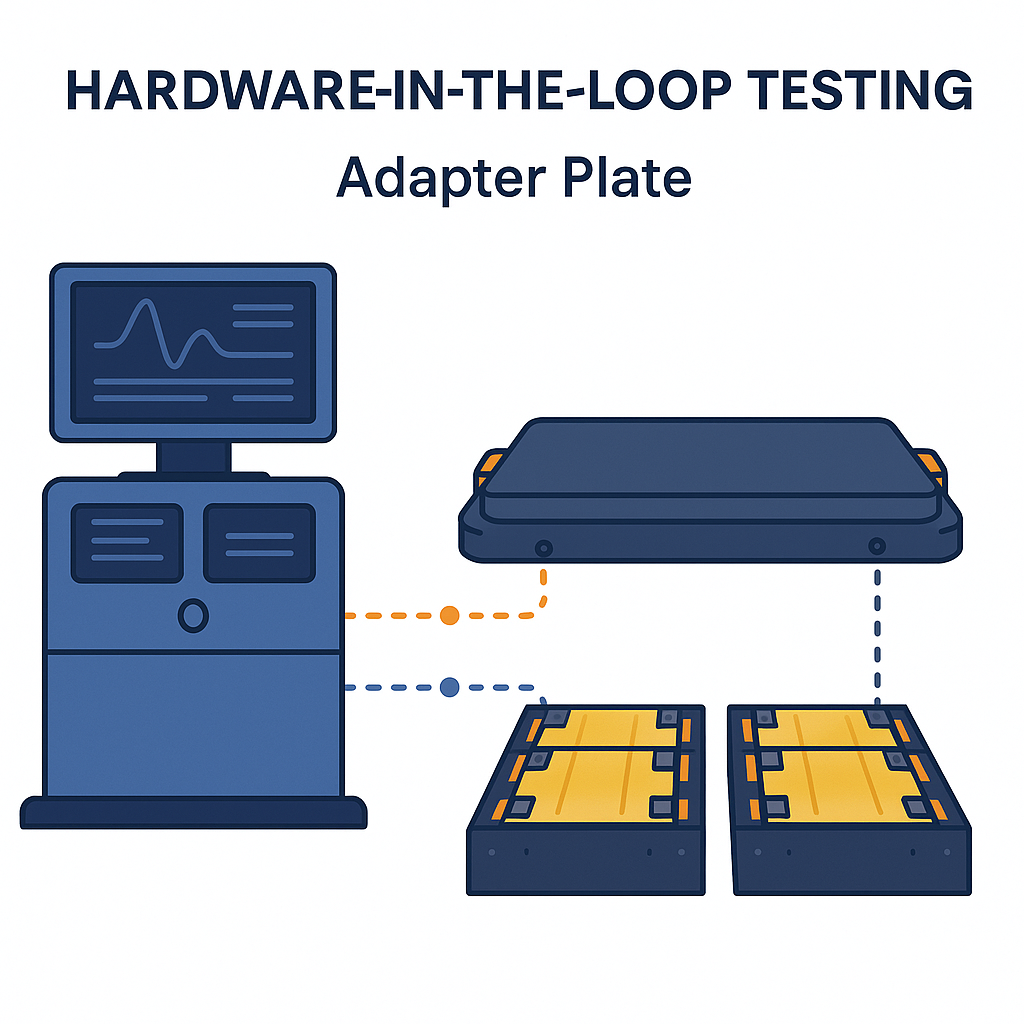

Battery Pack HIL

Developed Hardware-in-the-Loop testing system enabling comprehensive battery pack validation in controlled lab environments through high voltage testing, interface emulation, and automated production support.

Loading...

Technologies Used

software

PythonRobot Framework

hardware

Custom HIL hardwareHigh Voltage test equipment (ABC150)Chroma cell testerPEAK USB-to-CANUSB201 (USB DAQ)

protocols

CANPWM

Key Features Implemented

High voltage testing with production-level voltage and current capabilities

Interface emulation simulating CAN, GPIO, PWM, and vehicle-specific interfaces

Comprehensive safety monitoring and emergency shutdown systems

Automated test execution with scripted test sequences and pass/fail criteria

Production testing support for manufacturing quality assurance

Fault injection capabilities for robustness testing under failure conditions

My Role

Foundational HIL Development

Software Architect

Team Leadership

Impact

Complete Testing Coverage

Comprehensive battery pack functionality and safety validation

Manufacturing Support

Automated production testing for quality assurance